Fossil-fuel powered cars and trucks are the reason nearly half the population of the United States breathes in unhealthy levels of pollution.

Thankfully, there’s something we can do to change this.

By continuing to phase out conventional cars and trucks and transitioning to electric vehicles (EVs), we can reduce the pollutants we all breathe and the heat-trapping emissions that exacerbate climate change. States like California, Florida, and Texas are leading the way in EV adoption, with drivers in other states buying EVs in record numbers.

With this important transition underway the production of EVs and their batteries will increase the need for mined materials.

Electric vehicle battery materials

Most electric vehicle batteries are lithium-based and rely on a mix of cobalt, nickel, manganese, aluminum, copper, and graphite. As with any extraction and manufacturing, there are associated impacts. There is specific concern with the social and environmental impacts of mining and processing the minerals that are used in the batteries powering these vehicles, buses, bikes, and scooters.

It is important that in this transition, we strive towards the most equitable and sustainable future possible.

What can be done about EV battery sourcing issues?

First, companies must be held accountable for enacting and enforcing policies to only use ethically-sourced materials.

With smart policies, investments, and industry leadership, newly mined lithium needs can be reduced by nearly half (48 percent) from 2025 to 2050. By investing in battery recycling, EV efficiency, charging, battery innovation, and more choices of transportation modes we can reduce 1.5 million metric tons over the next 25 years, equivalent to 180 million of today's typically sized EV batteries.

Even with this reduction, there will still need to be an increase in mining to meet EV demand. Therefore, crucial changes are needed to reduce potential harm to mining- affected communities and to ensure Indigenous Peoples' right to self-determination when mining is on their land or affecting their natural resources. Measures include increased environmental regulations throughout mine development and the mining process; requirements for free, prior, and informed consent; and increased mineral tracing and auditing of mines.

Electric vehicle battery cost

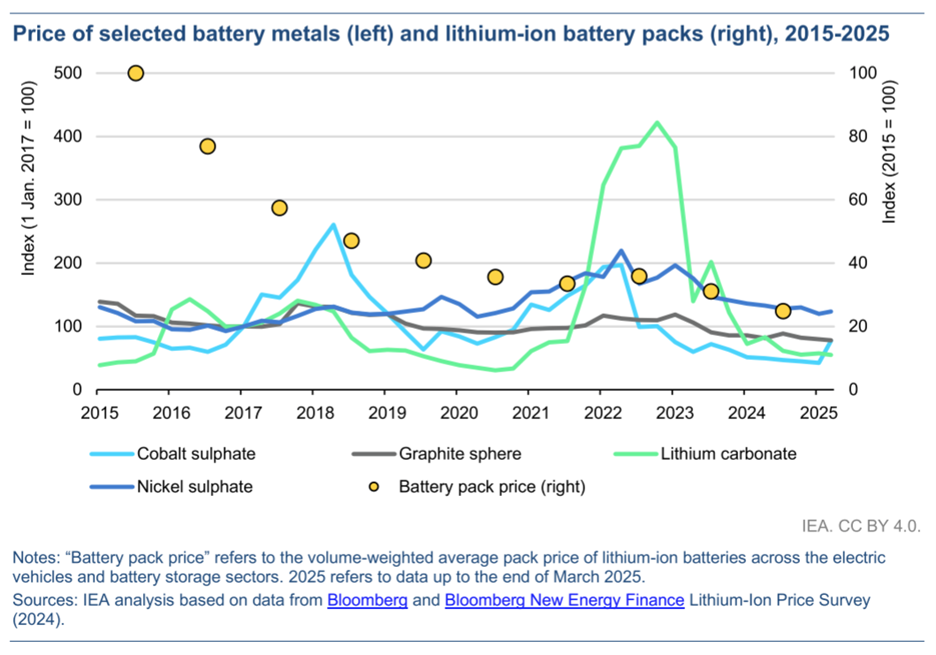

The price of lithium-ion batteries has fallen steeply as their production scale has increased, manufacturers have developed more cost-effective methods, and mineral prices decline. In 2024, pack prices fell a full 20% to the historic low of $97 per kWh for the average EV battery pack and $115 per kWh including all lithium-ion battery uses.

This rapid decline is even more impressive considering that when the first mass-market EVs were introduced in 2010, battery packs cost an estimated $1,000 per kilowatt-hour (kWh). Costs are estimated to continue declining with innovation, but increasing mineral demand will likely raise the costs of materials. Continued recycling of retired batteries will likely ease supply constraints and help keep mineral prices lower.

Electric vehicle battery lifespan

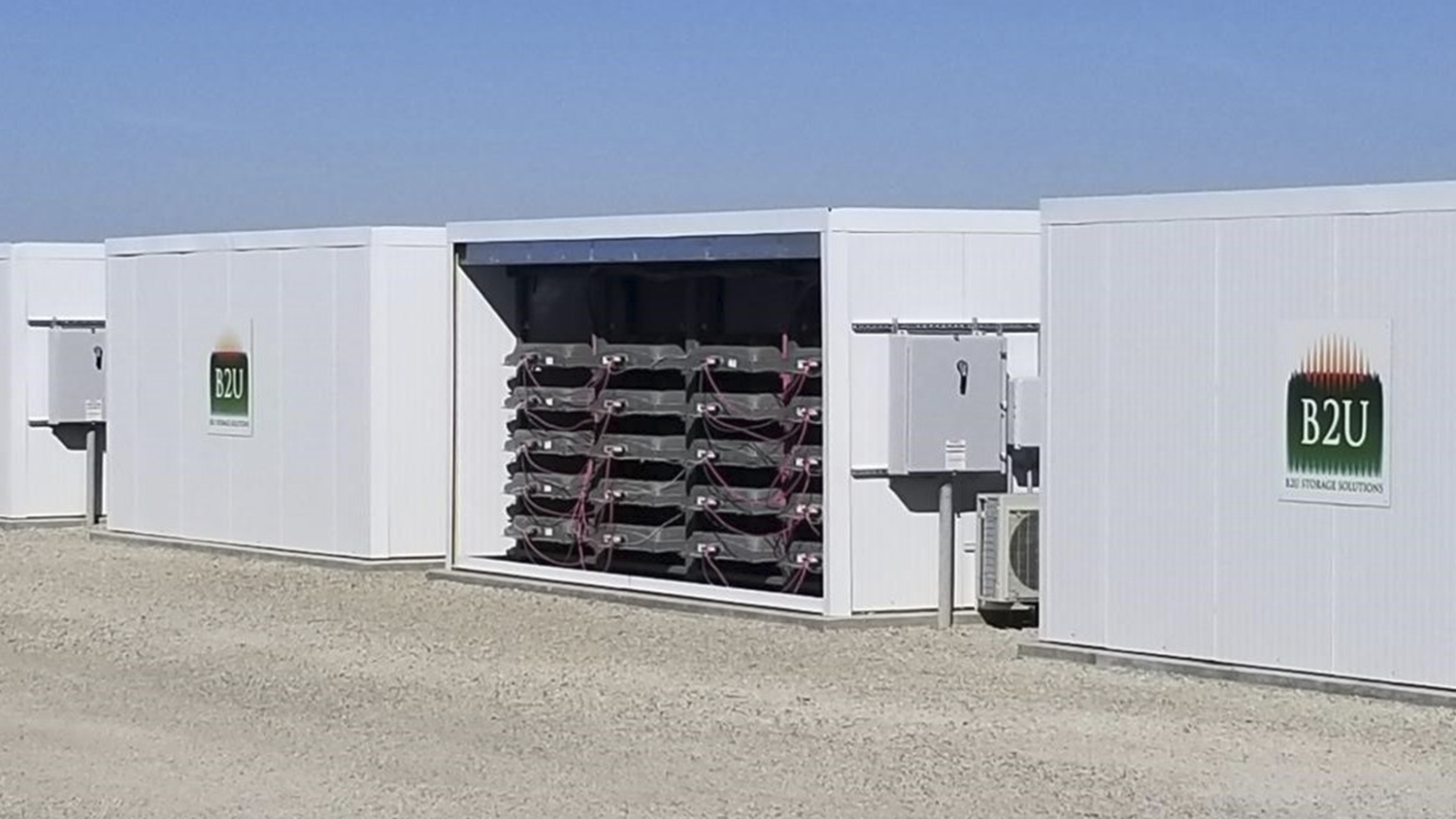

The lithium-ion batteries in EVs are designed for a long life and are expected to outlast the vehicle. Currently, most manufacturers are offering 8-year/100,000-mile warranties for their batteries, but current EVs are expected to have a similar lifespan to gasoline vehicles. Batteries from retired vehicles are now being repurposed for stationary storage, such as renewable energy support or for backup power in the case of a power outage.

Electric vehicle battery safety

EVs must undergo the same rigorous safety testing and meet the same safety standards required for conventional vehicles sold in the United States as well as EV-specific standards for limiting chemical spillage from batteries, securing batteries during a crash, and isolating the chassis from the high-voltage system to prevent electric shock. In addition, EVs tend to have a lower center of gravity than conventional vehicles, making them less likely to roll over and often improving ride quality.